Trudging through Manual Data Entry in a Manufacturing Environment

Its 6pm, after a long day on the shop floor. Your production manager, Steve, approaches you with a soft grin on his face, a bundle of production reports neatly stacked in his arms.

“Good for you,” you exhale just softly enough so that he can’t hear.

He is finished for the day, but it seems like for you, it’s only just begun. You estimate the size of the stack is roughly 25 layers deep. Without cutting corners and barring any issues, you should be able to go home by 8:15. The gnaw of tiredness and bed rest beckons to you, as it has been since 5:30 this morning. Cocking your head at Steve, you wonder what on earth you did to deserve being the key role here – the guy who manually types everything into the SAP system and then the same data into the MES.

“Isn’t there an easier way to put our production figures into SAP and just have the MES system magically know what we did?” you ask the man. Steve’s grin falls off slowly, as he shakes his head sullenly once, twice, three times.

These exchanges are quite common within the manufacturing industry because, until now, it’s been difficult to companies to find a definitive solution that helps with manual data entry and the synchronization of transactional records between MES and SAP.

This is where the team at Pangaea Solutions comes in – we enhance and simplify the connection to your MES system with our SAP Accelerator:

Integrated Manufacturing Execution System (IMES)

Our custom codebase ensures that when either of your systems generates IDocs, both the SAP system and the MES system remain in sync. Another important feature is that all the data in SAP is configurable based on plant and SAP specific instances. We adhere to the strictest standards possible, including the International Society of Automation’s standards for the interfacing between enterprise and control systems (“ISA-95”). Additionally, with SAP’s Fiori, your manufacturing employees can remain up to date on all the transactions taking place on the shop floor through a responsive web-based infrastructure. You could, for example, install tablet devices running the Fiori software and use them directly on the shop floor to save some time on post-process workflow. This could solve any issues of dual entry or employees working with data that doesn’t relate directly to their daily operations.

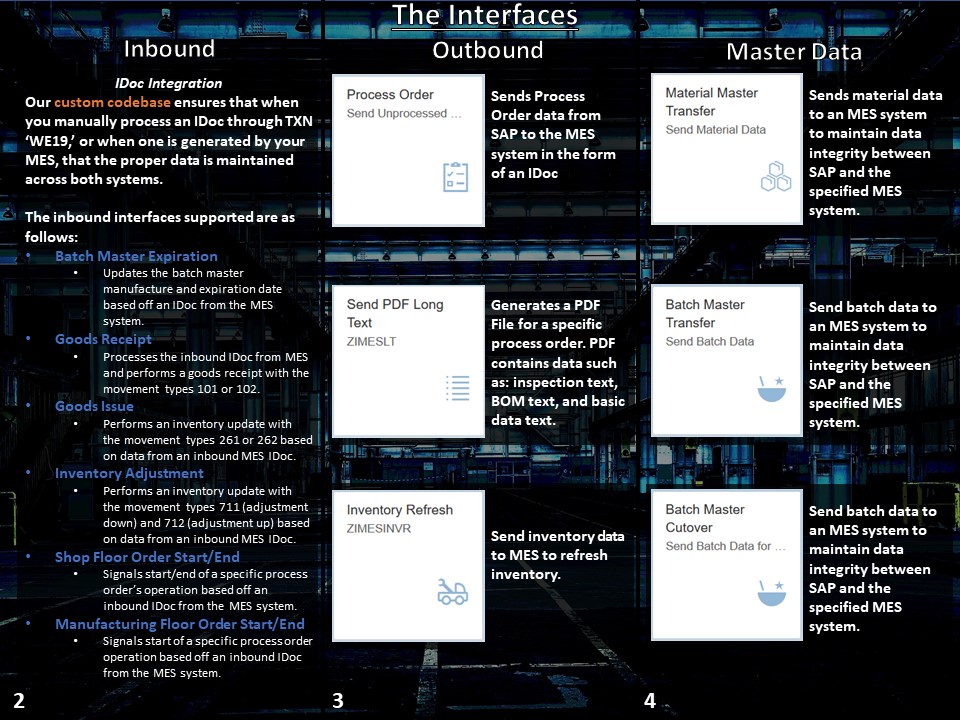

There are multiple interfaces included with this product, which manage both the outbound IDocs, as well as the Inbound IDocs between the SAP and the MES system. For example, on the left side below, we can see the blue items are inbound interfaces from MES to SAP, while the images represent the outbound interfaces from SAP to MES.

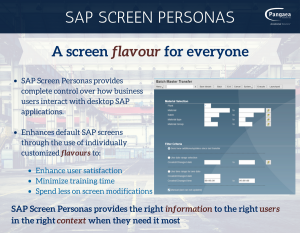

Fiori is not the only visual upgrade that IMES can provide to your SAP workspace. We also incorporate SAP’s “Screen Personas” which is a layer on top of the standard SAP GUI. This functionality allows your users to change “flavours” (screen layouts and visible fields) on a program-by-program basis for all the applications shown above. In this way, you’re able to customize how certain screens are displayed based on roles in your SAP system.

This is a significant upgrade from the original standard SAP interface, especially if your team doesn’t have access to the sometimes costly implementation of the Fiori web tools.

With the development of IMES, we sought to help manufacturers increase the efficiency and productivity of their operations by solving some common pains that employees face with SAP and MES. The level of integration and customization that IMES provides can make an immense, positive difference to a team’s workflow.

That wraps up the principles of the IMES offering. We hope we’ve inspired you to explore the ways this product could apply to your business. If you’d like to share your thoughts or some of your own strategies, please comment down below.

Looking to innovate your technology team’s organization skills? Take a look at our article “3 Powerful Structures to Organize Your Technology Team.”

Thomas Rautenbach, Architect

Thomas Rautenbach has over 20 years of diverse systems experience with a strong focus on system and integration architecture and software design and development. He has detailed technical, functional and system knowledge across the SAP technology platform, including extensive experience with the Finance, Supply Chain, Sales and Distribution, and Human Resources modules.

Follow Pangaea Solutions on LinkedIn